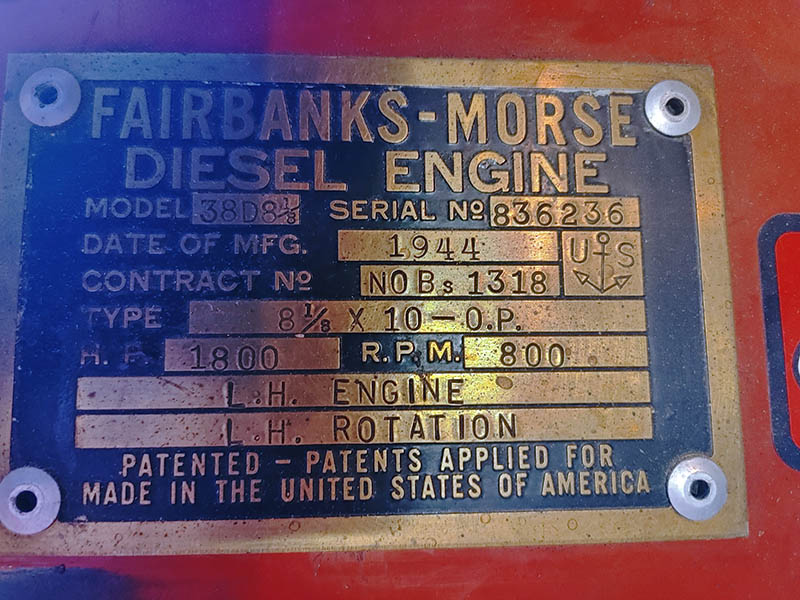

The Fairbanks Morse 38D8⅛

Two stroke oppose piston diesel engine

Authored by: Martin Leduc, August 2000

Brought to you by www.dieselduck.net, comments to [email protected]

While working for the Canadian Coast Guard, I had the opportunity to work on the CCGS Tanu. Tanu is 170' fishing patrol vessel. It was built in Victoria, BC, in 1968 by the Yarrows Shipyard. The design was based on a corvette hull, which was a popular warship design back in the second world war.

The main engines of the Tanu are Fairbanks Morse engines built in Dorval, Quebec. I had heard quite a deal about them, because they are of an interesting design for a diesel engine. The Tanu, along with it's sister ship on the east coast, have two such engines.

I

understand that these engines are somewhat common in

industry. It's welded design make this engine easy to

build and repair. At the time of it's introduction, the

size to power ratio was quite impressive. With the

slim, compact design it is easy to see

why they are found in the

railroad industry and early diesel submarines. The power

generation industry is also a common user of the opposed

piston engine.

why they are found in the

railroad industry and early diesel submarines. The power

generation industry is also a common user of the opposed

piston engine.

The Fairbanks Morse 38D8 1/8 on the Tanu is an inline eight cylinder engine although they are available in 4, 5, 6, 8, 9 10, 12 cylinder inline configuration. The bore measures 8 and 1/8 inches and the stroke is 10 inches. The total displacement of 1037 cubic inches per cylinder produces 170 bhp at 720 rpm. It is a two stroke, opposed piston engine. This means that there are two crankshafts in the engine, one at the bottom end, and one at the top end. The power developed in the cylinder is transferred to two pistons. One is connected to the top crankshaft and the other to the bottom crankshaft. The top and bottom crankshafts are connected through what is called a "vertical drive" situated at the driving end of the engine.

Valve covers, aka cylinder heads, do not exist with this engine. As with all two stroke engines, intake ports are cast into the cylinder liner. Additionally the cylinder liner also has exhaust ports. The exhaust and intakes ports are open and closed by the action of the two pistons. The intake ports are at the top while the exhaust ports are located at the bottom of the liner.

As

with all two stroke engines, these Fairbanks Morse cannot

function

without the help of a supercharger. On

these engines the positive charge of air is provided by a

single roots type blower. The blower is mounted on the

driving end and driven by the top crankshaft. The air is

distributed to the cylinders by way of an air intake

manifold situated along the intake ports near the top end

of the engine. The exhaust is collected by an exhaust

manifold near the bottom end, with the uptake taken from

the front of the engine.

without the help of a supercharger. On

these engines the positive charge of air is provided by a

single roots type blower. The blower is mounted on the

driving end and driven by the top crankshaft. The air is

distributed to the cylinders by way of an air intake

manifold situated along the intake ports near the top end

of the engine. The exhaust is collected by an exhaust

manifold near the bottom end, with the uptake taken from

the front of the engine.

Once the exhaust ports are exposed, the gas expansion, from combustion, ceases. The intake ports then become exposed allowing the positive charge of air to enter the cylinder. This chases, in a "uniflow scavenging" fashion, the exhaust gases out and prepares a fresh charge of air ready for compression. The upper pistons reaches "bottom dead center" 12 degrees after the lower piston, as they head on a collision course, compressing the fresh air in the cylinder.

At 9 degrees before top dead center, the

diesel fuel oil is introduce through two conical type

hydraulic injectors. The fuel is pressurize to 2000 -

2100 psi by a jerk type fuel pump. It is mounted upside

down and driven by a camshaft on the port side of the

engine. A Woodward governor controls the rack settings.

At 9 degrees before top dead center, the

diesel fuel oil is introduce through two conical type

hydraulic injectors. The fuel is pressurize to 2000 -

2100 psi by a jerk type fuel pump. It is mounted upside

down and driven by a camshaft on the port side of the

engine. A Woodward governor controls the rack settings.

The

engine has a capacity of about 725 liters of lubricating

oil. The oil is a standard "cd" or better, two

stroke motor oil. It is filtered thought a housing

containing 12 individual filters. The oil is then passed

through a oil cooler before

being sent back to the

engine. The oil pressure for this engine is around 23 psi

at full rpm (720). Additionally the oil is treated by an

Alfa-Laval oil purifier.

being sent back to the

engine. The oil pressure for this engine is around 23 psi

at full rpm (720). Additionally the oil is treated by an

Alfa-Laval oil purifier.

The engine is cooled by a closed system with a capacity of about 300 liters. The heat from that system is transferred to an open sea water system through a heat exchanger. Like most diesel engines the temperature is about about 78 - 82 Celsius in the engine.

The

engine is started by introducing compressed air at 1400

kPa (about 200 psi) into each cylinder. The compressed

air is introduced to the cylinder by way of a pilot valve

controlled by a distributor driven by the lower

crankshaft on the forward starboard side of the engine.

The power of the two engines is transferred to a common gear box through Vulcan Sinclair fluid couplers. These are of a British design, used extensively during the second world war. It behaves much like the torque converter in your car's automatic transmission. The gear is roughly a 3:1 ratio, which turns the controllable pitch propeller at about 250 rpm.

Coltec Industries in the United States have taken over the Fairbanks Morse engine line, as well as the Alco line. They can be found on line through Martin's Link Page.

I found theses pictures since I first wrote this piece, and now also have enough room on my web servers to put them up. Enjoy. Martin May 2007.

Here is a graphic illustrative video of the Fairbanks Morse and its major components.

| This picture illustrate the difference in size between the 8 cyl Fairbanks and the engine block of a 6 cylinder Caterpillar 3306, a similar size engine as found on large highway tractor trucks. |

|

| This diagram gives us a cross section (for-aft) of the Fairbanks. The heart of the operation is the cast iron liner, the rest of the engine is welded. Also note that there is two injection nozzle per cylinder. |

|

| This diagrams shows piston position during the one cycle. Notice the crank lead between the top and lower crankshaft. |

|

| These diagrams of the

roots type blowers found on the aft end of the engine, driven by

the top crankshaft. Air inlet is at the top.

|

|

Rocky Adams sends us his comments and input on this article in 2007

" These engines were originally designed so that you could remove the upper pistons out through the top just as you did with the lowers through the bottom. However, the US Navy, while negotiating a large contract with F-M told the manufacturer that the engine was four inches too tall to be serviceable in submarines. Fairbanks then redesigned the engine taking four inches out of the block height above the intake manifolds and shortening the upper connecting rods by four inches.

The difference between the

upper and lower crankshaft placements are obvious in the cutaway drawing

you provided. This allowed the engines to be installed in USN's

submarines. It also made removal of the upper piston much more difficult

because now the crankshaft was too close to the top of the cylinders to

give enough space. I'm sure you remember that to remove an upper piston

it must be separated from the 'dummy piston' inside it. the upper con

rod and the 'dummy' are then removed through the top of the engine but

the piston itself must be lowered down through the cylinder, after the

lower piston and rod assembly are removed, and taken out the bottom."

Carl sent this question in Aug 2018 (can anyone provide insight?)

Did F-M ever restore the design of this

engine

Going back

Also, if the design was good before the big

US Navy order, the molds etc. to

For your information, my interest in F-M O-P

engines is having seen a pair of the four-cylinder model in operation in

the retired Canadian Coast Guard Ship Ville Marie, renamed Heaven Bound

when purchased by a religious organization, now named Still Watch and a

privately owned pleasure vessel, believe it or not. If I am on board

again sometime I hope to record the serial numbers of the engines which

may be of aid in tracking their history.

"

The design

of the connecting rods never changed. The upper connecting rod on the

38D8-1/8 has remained 4 inches shorter to this day. Also, the serial

numbers that I have recorded for the engines placed in the CCG Ville

Marie are C-318 and C-319. By the way, the right cutaway image of the

roots blower that you have displayed is from a reversible engine; where

the engine and blower can turn either clockwise or counter-clockwise. I

hope this helps.

John sends us his comments and pictures, in 2010

" When I was in the Navy back in the 60‘s our Destroyer Escort had four of these engines and they were the 10 cylinder models.

When they were rebuilding one of the engines out at sea I noticed they were throwing some of the old pistons overboard. I talked them into giving me one. After cleaning it for days with emery cloth, I had it chromed and the ships name and all the guys in my division engraved on it.

Thought you might get a kick out of a few pictures of it. It is eleven and a half inches high, eight inches in diameter and weighs thirty five pounds. "

|

|

|

|

Tracey in San Francisco, in May 2011, sent us this link to US submarine diesel engine manual. From it, are the neat diagrams of Fairbansk Morse engines, below. |

|

|

|

|

|

|

|

|

|

You can also read about an Opposed piston renaissance in this 2010 paper. Below are pictures of a Fairbanks Morse engine in a USN submarine, open to the public in Portland Oregon. Click on the picture for a larger version.

|

|

|

|